Yachts For Sale

Any brand of yacht for sale. You can also use the search fields to find yachts by brand, state, length, year and price.

Yacht Overview

- Yacht Details Feadship

- Year 1964

- Location Newport, RI, US

- Engines 2

- Last UpdatedJun 13, 2024

- Asking Price$4,000,000.00

Have a question about this yacht?

Specifications

1964 Feadship 74′

First launched in 1964, Serena was the height of maritime cool in that heady decade. Almost half a century later, this Carlo Riva-designed Feadship was completely rebuilt and restored to better-than-new condition.

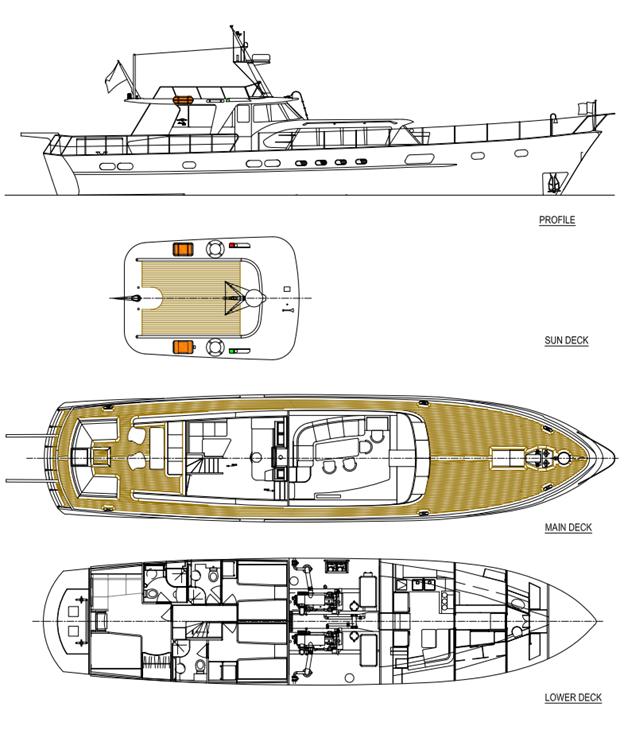

DIMENSIONS:

- Length O.A.: 22.5m/ 73’10”

- Length W.L.: 19.9m/65’3”

- Beam: 5.10m/16’9”

- Draft: 1.66m/5’5”

- Gross: 88

- Net: 73.8

- Year Built: 1964

- Builder: Feadship- De Vries

- Naval Architect: De Voogt

- Interior /Exterior Designer: Carlo Riva

- Construction: Steel & Aluminum

- Stateroom/Guests: 3 for 6 guests

- Crew: 3 bunks

- Cruising/Max Speed: 9kts ./11.5kts.

- Type: Displacement

- Flag: USA

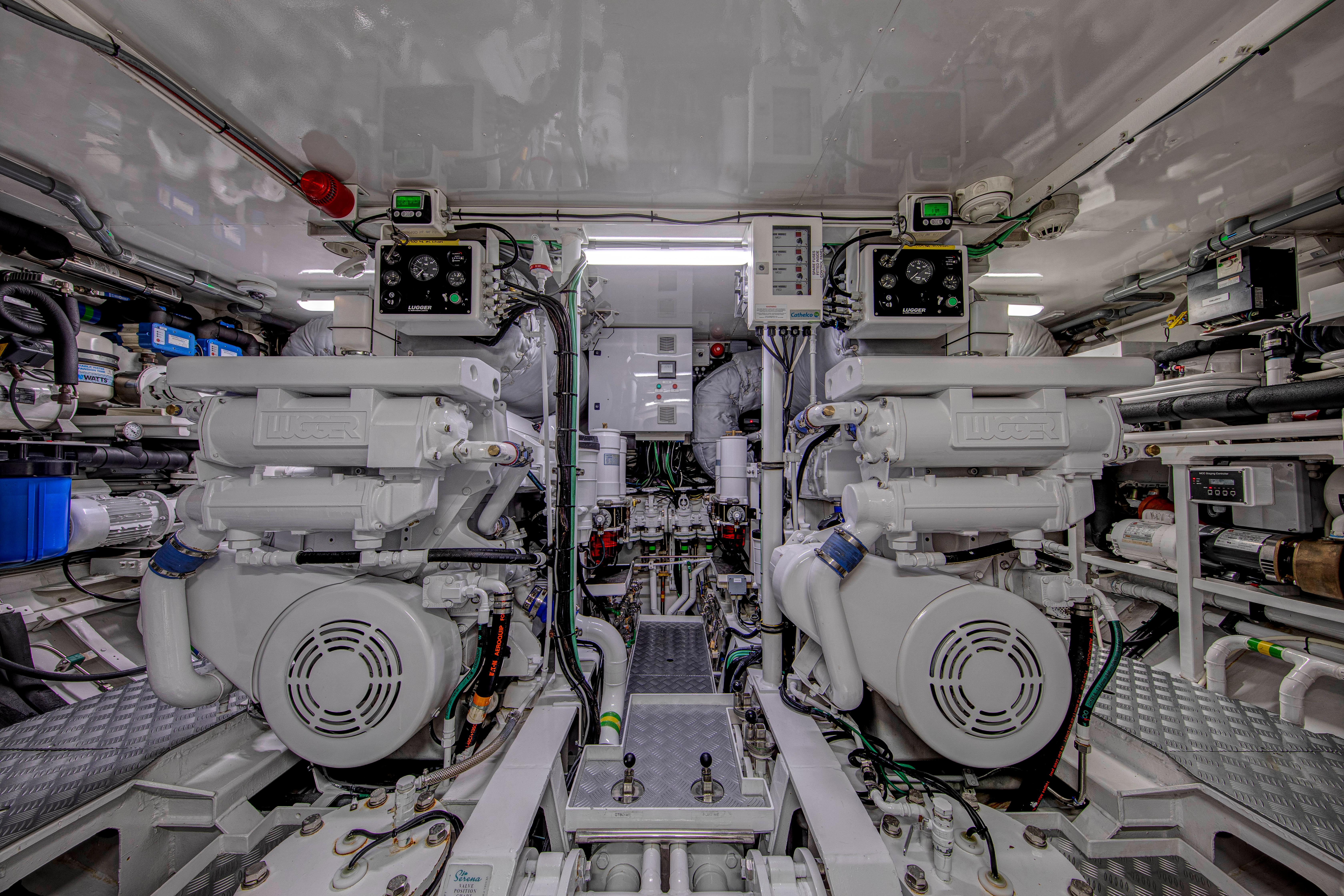

MACHINERY

- Main Engine: 2x Lugger L1276A2.1 (380hp)

- Main Engine Hours: Port 5089 Starboard 5085

- Gear Boxes: Twin Disc- MG5114SC

- Shafts: 2 piece Stainless Steel

- Propellers: 4 blade Bronze

- Speeds/Fuel Consumption: 10Kts – 1300 RPM / 14 GPH / 40% Load (ocean)

- Range: 900nm at 10kts

- Main Generators : Northern Lights M844LW3 – 16KwGenerator

- Hours: Port – 2422Stbd.-2447

- Electricity: 220v – 50hShore Power

- Custom Magnus shore power converter for US 110v single phase power

- Batteries

TANK CAPACITIES

- Fuel: 1300 gallons

- Water: 600 gallons

- Grey Water: 100 gallons

- Black Water: 50 gallons

- Water Maker: Dometic Sea Exchange Model No.XZII 1200/2000Z

- Steering System: Simrad AP44

- Rudder Angle Indicator: Simrad AP44

- Thruster: Side Power PPC840 550A

- Stabilizers: Niad 254 (No at anchor capability)

- Fuel Filters: Racor dual

- Bilge Pump: Central manifold and individual DC float controlled

- Fire Pump: Central manifold w/ 2 stations on deck

- Sewage Treatment: Tecnicomar- EcomarWC’s 3 guest and 1 crew

- Air Conditioning: 2x Dometic 3 Ton chillers (MCGXLP36 2363)

- Ventilation: Individual extraction in each head and an extraction hood in the galley ER equipped with Automatic Murray ventilation system

Safety and Security Equipment

- Exterior: CCTV cameras

- Medical: 1 MedAire coastal kit

- Fire: 3 fire suppression systems located in the Engine Room, Lazarette and Galley

- Monitoring: RHODIUM AMCS 2018

- Cellular System: 2 4G cellular data cards through a pepwave

- VHF Radiotelephones: 2 Icom IC-M506

- Crew Comms: 2 Standard hand held VHF and 4 Icom UHF Radios

- Automatic Pilot: Furuno Nav Net TZ touch2

- Log: Furuno Nav Net TZ touch2

- Echo Sounder: Furuno Nav Net TZ touch2

- Radar: Furuno Nav Net TZ touch2

- Chart Plotter: Furuno Nav Net TZ touch2

- GPS: Furuno Nav Net TZ touch2

- Wind Instruments: Furuno Nav Net TZ touch2

- AIS: Furuno Nav Net TZ touch2

- Anchor Windlass : ORVEA EK3524Horizontal axis windlass/ Double Gypsy and vertical stainless drum.

- Aft Warping Capstans: 70m / chain port & Stbd

- Boat Crane and Davits

Audio/Visual Entertainment Systems

- Starlink

- Main Salon: 1 TV on motorized lift with Apple TV

- Bridge Deck Lounge: Overhead speakers

- AV Owner’s Cabin: 1 TV with overhead speakers

Domestic Equipment

- Main Galley: 2x Liebherr Fridge Freezer combo’s

- 1x Viking convection Microwave oven

- 1x Miele 6 plate induction stove top

- 1x Miele Radiant Oven

- Laundry: 1x Miele WT 2780 washer/dryer

- Pantry: Forward Bilge storage

- Ship’s Safe: 1 in Masters cabin

- Tenders: (1) 15ft. Novurania RBI

WORK HISTORY

2022

- Exterior / interior paint (2018-2022)

Vessel had full paint job with Awlgrip 2000. Vessel has been kept under cover during last 2-yard periods and ceramic polish applied to all painted surfaces.

- Bilges paint (2020-2022)

All bilge areas have been treated and new coatings applied throughout.

- New Lithium house batteries The house batteries were 2 cell gel batteries. To minimize weight in the stern of the vessel and gain storage area in the lazarette these batteries were switched out for new lithium-ion batteries.

- Bow thruster and Lithium batteries

A new electric bow thruster was installed to assist in docking maneuvers and powered with its own set on lithium-ion batteries and charger. A cooling fan was added to keep the bow thruster electric motor cool and maximize the run time of the motor without overheating.

- LED lights upgrade

All interior lighting and exterior deck lighting has been converted to LED type to minimize power consumption and heat.

- New underwater lights

Originally the vessel had a single underwater light at the side boarding ladder. 3 additional lights were added on the transom and port side for symmetry. All the light were weld in fittings with LED fixtures.

- Toolboxes There are tight storage areas forward of the engine compartment. Custom sliding toolboxes were designed and installed to utilize valuable storage areas behind the toolboxes when in place.

- Pasarelle

With the change in the davits, the passerelle was upgraded to operate with a cross bar which allows for the passerelle to be raised and lowered using the davits. The entire passerelle had new hardware fabricated and installed to preserve the structural integrity of the platform. Swivel hinged wheels were installed for greater stability when in use.

- Pumps replaced (2021-2022)

All pumps (sea water, fresh water, black and grey water) have been serviced / overhauled or replaced if required during this yard period. New CuNi discharge tree fabricated.

- Pilothouse air handler

During use of the vessel last summer, it was noted the pilot house could not be cooled down, an additional air handler was installed in the salon and ducting routed to the pilot house. This unit was sized according to the capacity of the chiller plant. The salon air handlers were also replaced.

- Windlass serviced and new electric motor

Windlass has been overhauled with new bearings and electric motor.

2021

- New generators

The old generators were 1 @ 16kw and 1 @ 10 kw. The owner wanted to have the ability to run on a single generator most of the time only bringing the second online as needed. We installed 2 new 16kw with the ability to load share and shed as needed for the addition on galley equipment and the redundancy of the generators.

- New shore power unit

The small shore power unit installed in 2018 was not sufficient for the shore power loads the vessel was seeing, and it was an air-cooled unit creating excessive heat in the lazarette area. The new unit can take 100-amp shore side power and provide the vessel with all the power required. This unit is also liquid cooled. The input has been split between 2 50-amp cords to allow the vessel mooring in smaller marinas where a 100-amp service may not be available.

- Main Switchboard upgrade and electrical revision with the upgrade to new generators and new shore power unit, the main switch board was overhauled / converted to accept the new inputs for both sources. This also allowed for the parallel and seamless transfers of the ship to shore power.

- Ships alarm and monitoring system The monitoring system originally installed by Feadship was upgraded with a new software upgrade, interfaced with the generators, and interfaced with the new power management system.

- Galley transformer 110VAC

A new cook top and microwave were added to the galley. These are 110v 60htz appliances. A transformer was added to the vessel for these 2 units and allowed for a few 110v convenience outlets through the galley area.

- New rudders

During rudder removals for inspection, it was noted the steel rudder shafts were heavily pitted and the steel rudder blades had seen better days. New stainless-steel rudders were designed and fabricated. The shafts were made of Aquamet 22 and the blades were fabricated from 316 stainless.

- ER and Lazz ventilation

The original ventilation system in the engine room was not adequate for the addition of more machinery and did not have a demister system to keep salt air / water from entering the machinery space. Additional holes were cut through the hull side to allow for more air flow while being hidden behind the existing decorative clam shells on the hull side.

New more powerful fans were installed along with a demister system. These fans are automated working from engine room temperature and pressure.

- New stainless-steel davits

The original davits were painted steel with a rake of approximately 160 degrees. The owner felt this interrupted the flow of the vessel lines and asked to have the davits at 90 degrees. New davits were designed, load tested and installed using 316 polished stainless steel. A securing system was also developed to keep the tender rigid when in the stowed position.

- New stainless-steel cutwater A new stainless-steel cutwater was added to the stem of the vessel to help prevent the chafing of anchor chain on the painted surface of the vessels stem.

- Oil change system An oil change system with manifold and pump were installed for both engines, both generators and both gears. Permanent plumbing runs have been installed to the manifold and the pump.

- MSD sewage treatment plant Previously the vessel had no sewage treatment system on board. With the eco concerns of various ports / harbors and the owners concern for the environment, a sewage treatment system has been installed and plumbed to the black and grey systems of the vessel.

- Stabilizer upgrade The stabilizer control system and software has been updated for the purpose of improving the performance of the existing stabilizer fins.

- CCTV A new CCTV system (5 cameras) 2x ptz in the machinery space and 3 x fixed cameras on the deck was added including custom made housings to blend with vessel design and recording capability.

- Water heater / boiler With the replacement of the generators, new stainless steel dual element hot water boiler was installed and configured to fit the allowable space in the engine room

- Spot zero / Watermaker A new 2 membrane water maker was installed which incorporates a spot zero water purifying system.

- Valves revised, bilge manifold rebuild (2020-2021) All valves were removed and replaced with new valves. The sea water valve design was based on original as there is not swing room for the valve handles near the sea chest. Custom tools were made and secured next to the valve area. All parts were fabricated from 316 stainless-steel. Seachest was reconditioned, and ceramic coatings added to the inside. All thru hulls below water line have also had ceramic coatings applied to the interiors.

- Steering hydraulic pump serviced, ram serviced, Emergency steering and lock

for rudder (2022-2021)

- Entire steering system including pump has been overhauled and parts replaced as required. A new purchase system has

been installed to center and lock rudders in the event of steering failure.

2018

- New anchors and anchor chains The old, galvanized anchors and chains were replaced with stainless steel.

- Originally the engine room had an FM 200 system installed. This system was relocated to make way for the new chiller plant. Additional fire systems were installed (1 for the gally cook top, and 1 for the lazarette area.) These are independent systems from the engine room system.

- Fixed firefighting x3 (2018-2021)

- Awnings x3 (2018-2022)

The owner requested 3 areas of the vessel have awning to prevent direct sun exposure to the guests. Awnings were designed and removable carbon poles used to support the canvas in these areas. The receivers for these poles have been designed to stay in tune with the vessel design and some removable for storage when not in use.

- Anchor locker steel repairs Through investigation of the forward chain locker, some of the bow plating was found to be failing as the interior coatings had not been maintained. These sections of shell plate were removed and replaced with new steel. All welding andplate were performed at a Lloyds class level.

- Appliances (2018-2022) A new microwave and electric cook top have been installed to replace the propane cook top originally installed.

- Nav Comm (2018-2022) All nav comm equipment has been upgraded to the latest technology along with AIS, Nav Tech, Furuno Nav net chart plotter and new VHF radios. All antennas have been replaced. Portable back up for navigation has been installed.

- New chiller plant

A new chiller plant was installed with new chiller lines and all air handlers serviced.

- Fashion Plates New fashion plates were designed fabricated and installed to keep in stride with the original vessel design.

- Pilothouse console Starboard side of console was designed and built to match existing console in order to fit an additional navigation screen.

- Pilothouse table An adjustable sliding table was designed and installed as per owners request to ease entry into and out of booth type seating.

- Master bed mods

The port master bed has been converted into a sofa lounge area as per the owner’s request.

Disclaimer

Bluenose Yacht Sales offers the details of this yacht in good faith but cannot guarantee or warrant the accuracy of this information nor warrant the condition of this boat for sale. A yacht buyer should instruct his yacht broker, or his boat surveyors, to investigate such details as the buyer desires validated. This yacht for sale is offered subject to prior sale, price change, or withdrawal without notice. Bluenose Yacht Sales is pleased to assist you in the purchase of this vessel. This boat may be listed with another yacht broker.

×

Get More Info on

×

Share With a Friend

×

Price Watch:

Have any inquiries about the above boats?

We can help.

Contact bluenose yachts today for special sailboat pricing!

Boat Inquiry

Contact us to learn more about our offered sail & power boats.